In the intricate world of manufacturing, choosing a machine shop can be challenging. Whether you’re a seasoned industrialist or a fledgling entrepreneur, the choice of a machine shop can significantly impact the quality, cost and timeline of your project. With so many options available, it’s crucial to know what to look for when navigating this terrain. Here are some key factors to consider:

-

- Expertise and Experience. At the heart of any reputable machine shop lies a team of skilled craftsmen. Look for shops with a track record of experience with similar projects. A shop’s expertise in machining processes, materials and technologies can make all the difference in achieving precise results.

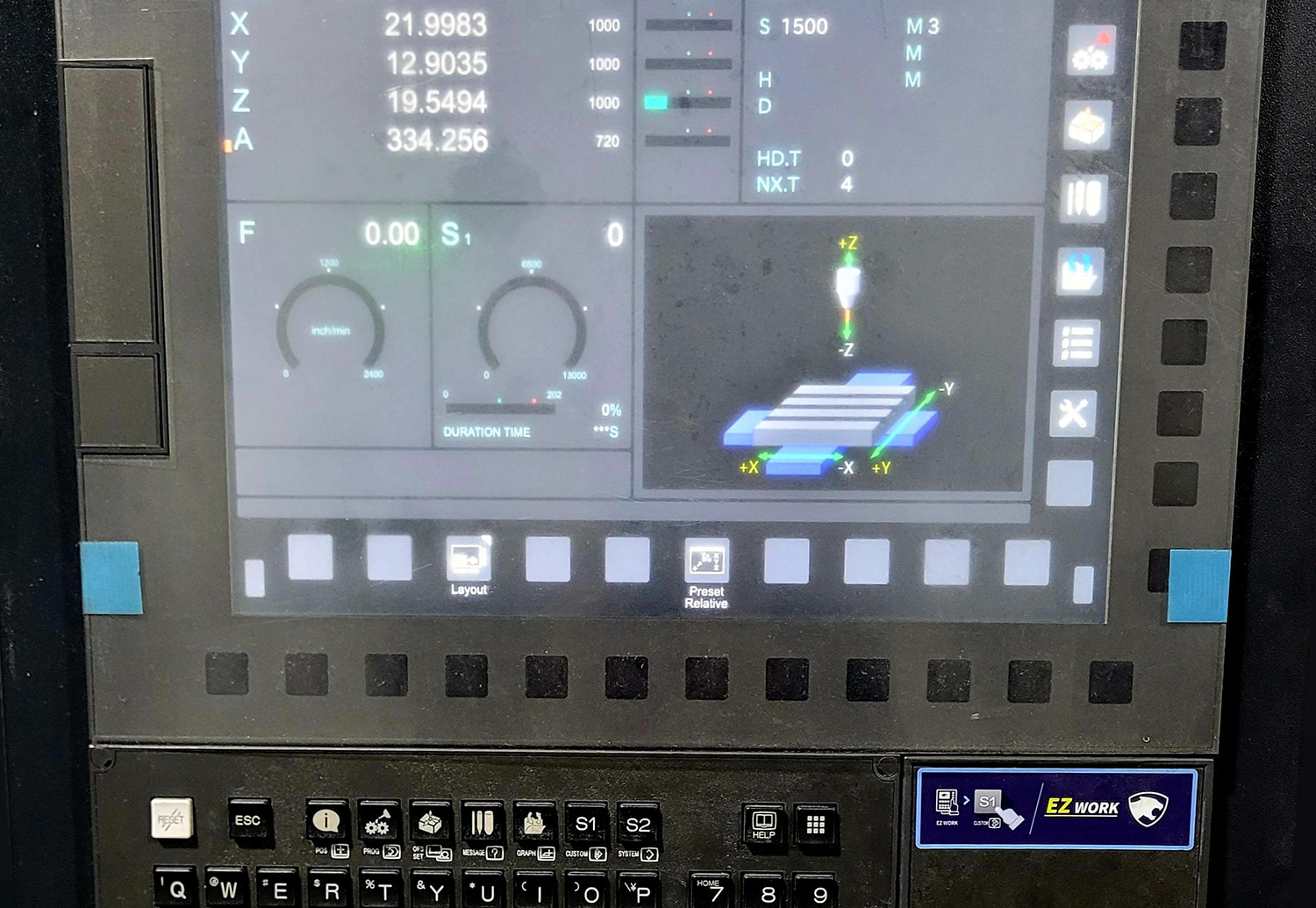

- Technology and Equipment. A modern machine shop should be equipped with late-model machinery and tools. Advanced technologies such as 4-axis CNC milling, live tooling capabilities and CAD design with Mastercam or SolidWorks are essential for producing intricate and accurate parts. Assess the shop’s capabilities and ensure they align with your project requirements.

- Quality Control Standards. Quality is non-negotiable in manufacturing. A reputable machine shop will have a commitment to the highest standards of quality – including the use of American-made steel and similar materials – to ensure that every part meets exact specifications and tolerances.

- Flexibility and Customization. Every project is unique, and a good machine shop should be able to accommodate custom requests and adapt to changing requirements. Whether you need a prototype, a small batch of parts, or large-scale production, choose a shop that can tailor its services to suit your needs.

- Communication and Collaboration. Effective communication is essential for a successful partnership. Choose a machine shop that values transparency, responsiveness and open dialogue. A shop that actively collaborates with clients throughout the manufacturing process can help identify potential issues early on and ensure alignment with project goals.

- Cost and Pricing. While cost is undoubtedly a factor, it should not be the sole determinant in choosing a machine shop. Instead of focusing solely on the lowest price, consider the overall value proposition, including quality, reliability and customer service.

- On-time Delivery. Creating a precision-machined part to a customer’s exact specifications is the key to success for a machine shop – unless that part is delivered AFTER the customer’s deadline. When choosing a machine shop, consider not just its tools and technology but also its track record for meeting deadlines.

- Location and Logistics. The location of the machine shop can impact shipping costs, lead times and overall convenience. Consider proximity to your facility or distribution centers, especially if you require frequent visits or quick turnaround times. Additionally, evaluate the shop’s logistical capabilities to ensure smooth coordination and delivery of parts.

- Reputation and References. Word of mouth speaks volumes in the manufacturing industry. Seek recommendations from colleagues, partners, or industry associations to identify reputable machine shops with a proven track record of excellence. Online reviews and testimonials can also provide valuable insights into past clients’ experiences.

In conclusion, choosing the right machine shop is a critical decision that can profoundly impact the success of your project. By considering factors such as expertise, technology, quality control, flexibility, communication, cost, delivery timelines and reputation, you can make an informed choice that aligns with your needs and objectives. Remember, the right machine shop isn’t just a vendor; it’s a strategic partner in your journey towards manufacturing excellence and business success.