In the manufacturing industry, precision is paramount. Whether crafting intricate components for industrial equipment or fashioning sturdy parts for the oilfield, the processes involved must be exact and efficient. Among the various techniques employed in modern machine shops, milling, turning and fabrication stand out as fundamental methods, each with its unique characteristics and applications. Understanding the nuances of these processes is important for optimizing production and achieving desired outcomes.

Milling: Precision in Motion

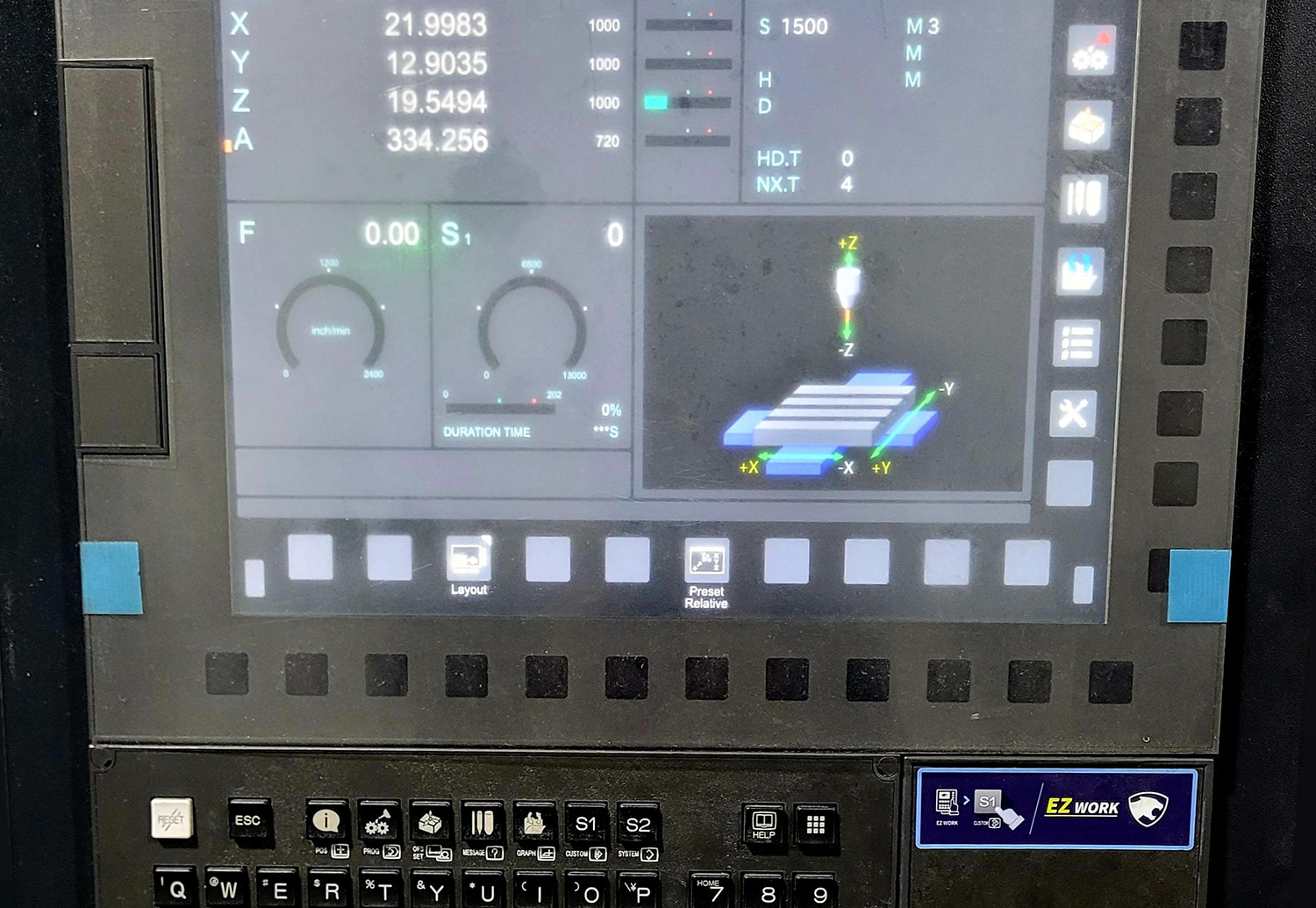

Milling is a versatile machining process where a rotary cutter removes material from a workpiece to create complex shapes and profiles. This subtractive manufacturing method involves a stationary workpiece and a rotating cutting tool, typically with multiple cutting edges. The tool’s movement can occur along various axes, allowing for precise dimensional control and intricate detailing.

One of the key advantages of milling is its ability to produce a wide range of geometries, from simple holes and slots to intricate contours and surfaces. This flexibility makes it indispensable in a variety of industries where precision and consistency are paramount.

Turning: Shaping with Rotation

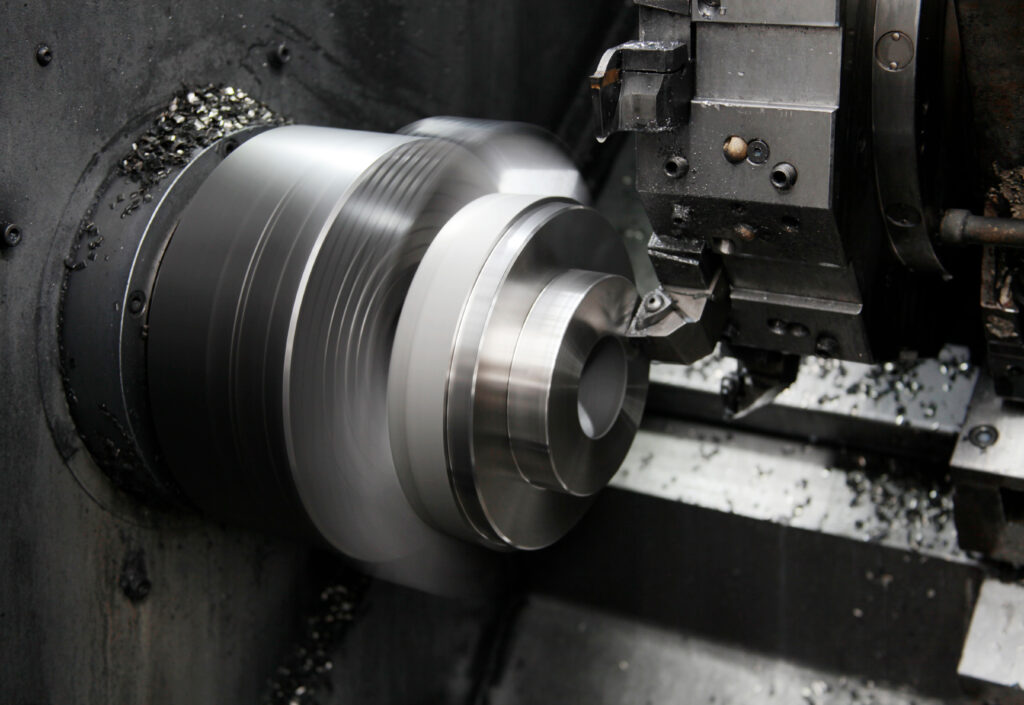

In contrast to milling, turning involves rotating the workpiece while a cutting tool traverses along its surface to remove material and create cylindrical shapes. This rotational motion enables the creation of components such as shafts, pins, and threaded rods with remarkable efficiency and accuracy.

Turning is particularly well-suited for producing symmetrical parts with rotational symmetry, such as gears and pulleys. Its high-speed, continuous cutting action allows for rapid production while maintaining tight tolerances, making it a cornerstone of mass manufacturing processes across many industries.

Fabrication: Crafting Complexity

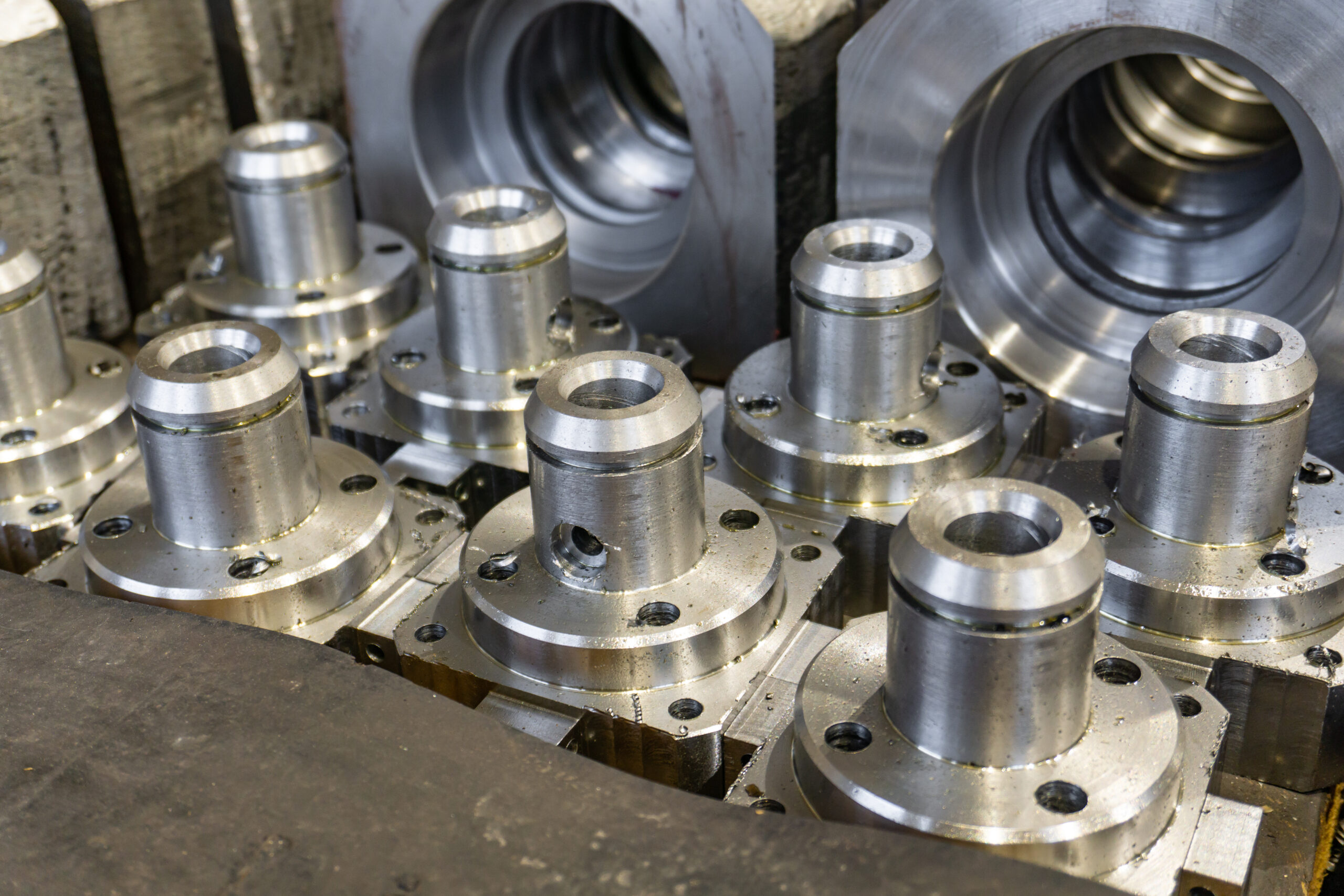

Fabrication encompasses a broad spectrum of processes aimed at shaping raw materials into finished products through cutting, bending, welding and assembly. Unlike milling and turning, which primarily focus on machining operations, fabrication involves both additive and subtractive techniques to achieve desired shapes and structures.

Welding, for instance, joins metal components together through the application of heat and pressure, creating strong and durable connections vital for structural integrity. Meanwhile, cutting methods like laser cutting and plasma cutting precisely carve out intricate designs from sheet metal or other materials, enabling the creation of custom components with intricate detailing.

Milling, Turning and Fabrication: Differentiation and Integration

While milling, turning and fabrication each offer unique capabilities and advantages, they are not mutually exclusive. In fact, modern machine shops often integrate these processes seamlessly to optimize efficiency and accommodate diverse production requirements.

For example, a manufacturing project may begin with milling to rough out the basic shape of a component before transitioning to turning for finer detailing and dimensional accuracy. Subsequently, fabrication techniques like welding and assembly may be employed to integrate multiple components into a cohesive assembly.

Conclusion: Precision in Harmony

In the intricate dance of manufacturing, milling, turning and fabrication play indispensable roles, each contributing to the creation of complex components and assemblies with precision and efficiency. Understanding the nuances of these processes empowers manufacturers to select the most suitable techniques for their specific needs, whether it’s crafting intricate aerospace components or producing robust automotive parts. By embracing the synergy between milling, turning and fabrication, machine shops can unlock new levels of productivity and innovation in the ever-evolving landscape of manufacturing.

Located in the heart of Central Oklahoma, Pro Force Machining offers all of these machining processes to fit the unique needs of each customer. To understand the full scope of the services Pro Force offers, or to get a quote on an upcoming projects, contact the Pro Force team today!